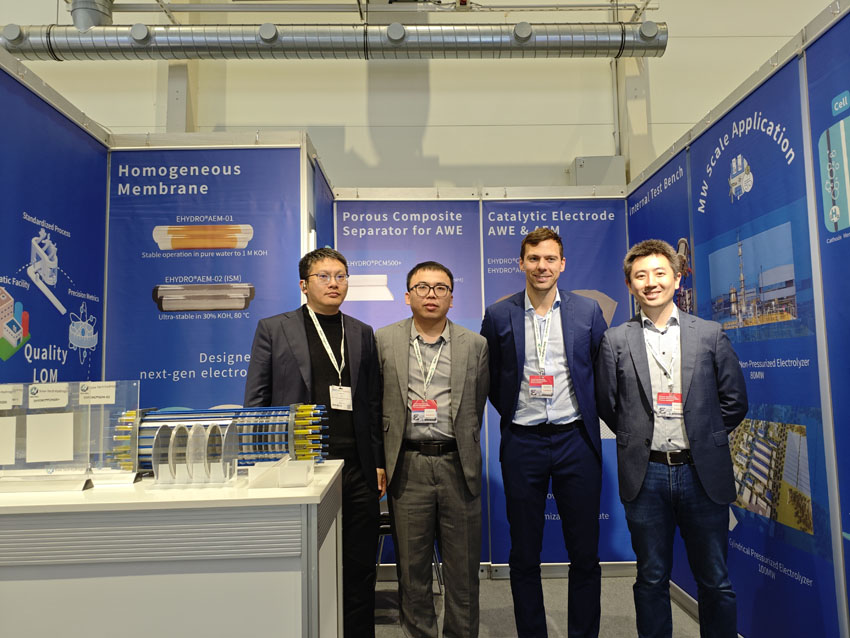

From October 21st to 23rd, 2025, the Hydrogen Technology Expo Europe was successfully held in Hamburg, Germany. As a barometer of global hydrogen technology development, this year's exhibition brought together leading companies and the latest innovations from across the industry chain. Making its debut as an exhibitor, Sino-Tech Hydrogen, led by CEO Dr. He Qingyi and CMO Dr. Yu Zhiwei, attracted widespread industry attention with its unique technological positioning and robust product capabilities, achieving results that far exceeded expectations.

Comprehensive Portfolio Demonstrates Material Innovation Strength

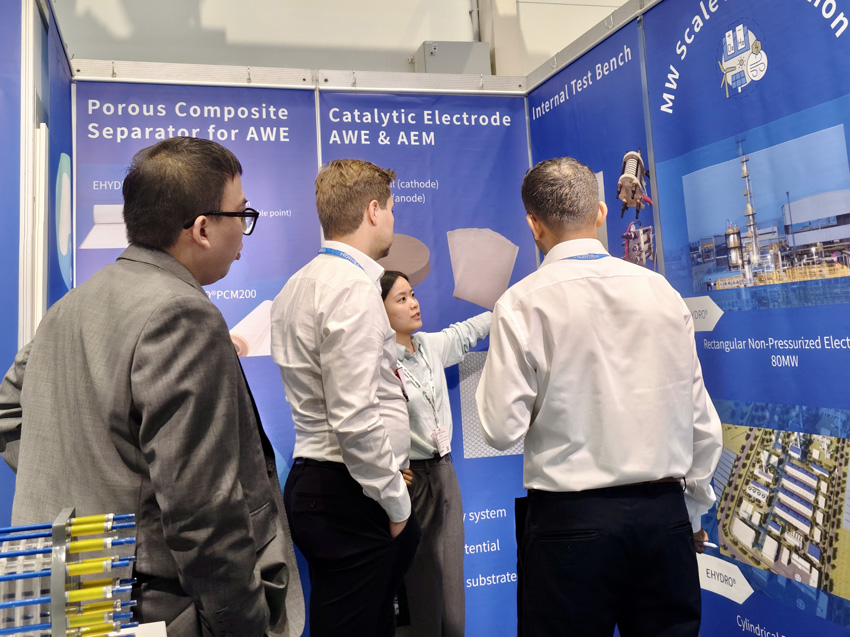

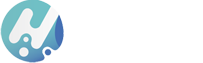

As the only materials supplier capable of providing integrated solutions for both Alkaline Water Electrolysis (AWE) and Anion Exchange Membrane (AEM) systems—including membranes and catalytic electrodes—Sino-Tech Hydrogen's booth drew numerous visitors and industry peers for in-depth exchanges. Its mass-produced products, such as the EHYDRO® PCM composite separator, EHYDRO® Coral series, and ANO series catalytic electrodes, with an annual capacity of 500,000 m² and performance data validated over six months to a year in real-world projects, impressed many alkaline electrolyzer manufacturers.

New Products Precisely Meeting European Demands

Addressing the European market's clear demand for high efficiency and low internal resistance, Sino-Tech Hydrogen's newly launched PCM200 product in 2025 garnered significant interest. It has now entered the pilot-line stage, with samples provided to over ten domestic and international clients. Ongoing technical exchanges continue to drive process optimization.

Diverse Electrode Solutions Tailored to Customization Needs

Sino-Tech Hydrogen showcased electrode solutions optimized for the European market. The coral-i Raney Nickel catalyst, coral-II ternary cathode catalyst, and ANO-I catalyst can be applied not only to classic nickel meshes but also to substrates such as porous nickel plates, meeting specific European customer requirements for mechanical strength. Thanks to in-depth interactions with overseas clients since 2024, all types of substrate electrodes have received customer testing feedback, providing continuous positive input for R&D and production. Currently, the maximum electrode width has reached 2.1 meters, fully meeting diverse client needs.

Forward-Looking AEM Technology Paving the Way for Future Applications

AEM technology, regarded as a key future direction for hydrogen, combines the technological maturity and cost-effectiveness of AWE with the high efficiency and dynamic response of PEM electrolyzers. Its inherent compatibility with fluctuating renewable energy sources—such as wind and solar—enables more flexible and efficient conversion of green electricity into green hydrogen. Consequently, Sino-Tech Hydrogen's exhibited AEM ion exchange membranes, ISM (Ion Solvent Membrane), and AEA electrodes attracted numerous detailed inquiries. In addition to the AEM01, suitable for low-concentration alkaline AEM water electrolysis environments, the performance of the ISM membrane under high-temperature, high-concentration alkaline conditions sparked extensive technical discussions and exploration of potential application scenarios.

Sensing Market Momentum, Reinforcing Commitment to Green Hydrogen

Through this exhibition, Sino-Tech Hydrogen gained a deep sense of the vitality and potential of the European hydrogen market—where the entire industry chain is flourishing, leading companies are rolling out iterative technologies, and new players are continuously entering the field. Sino-Tech Hydrogen is fully confident in the future of green hydrogen and remains committed to advancing the industry with high-quality products and technologies, collaborating with all stakeholders to contribute to the global energy transition.